OPTIMAL CONNECTIVITY offer solutions for DTS, DAS and DVS

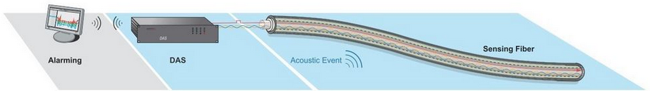

Integrated Distributed Sensing means Distributed Temperature Sensing (DTS), Distributed Acoustic Sensing (DAS), and Distributed Vibration Sensing (DVS) performed in a single fiber optic sensor cable with dedicated fibers for each technology. These sensor cables can stretch over lengths of up to 50 km only depending on the link budget of the active components. The sensor cable acts as linear sensor for temperature, acoustics and vibrations. It can also detect mechanical data like stress, strain and bending. Important to mention that the entire sensor cable acts as a linear sensor providing a linear/special resolution of the location on the sensor cable.

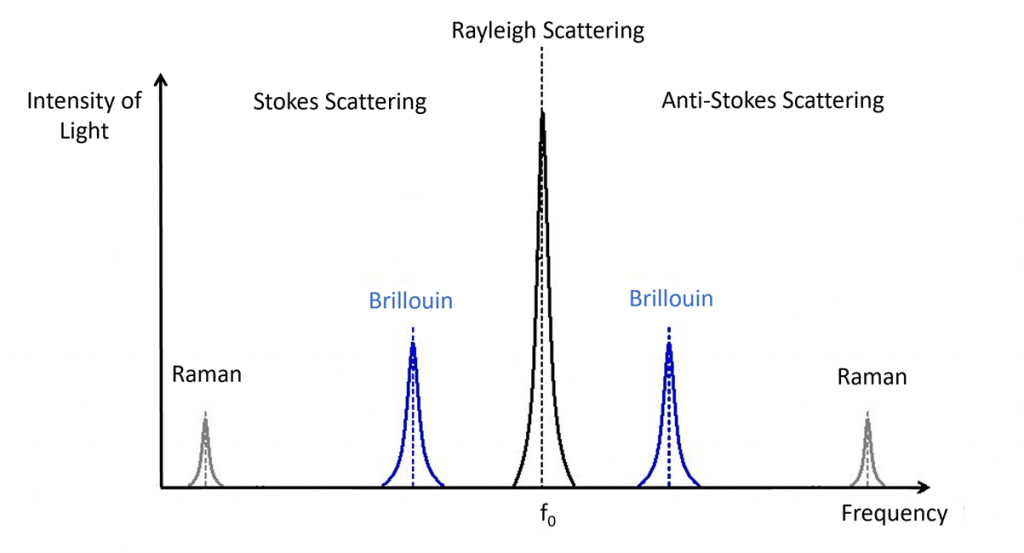

DAS and DVS are using Brillouin scattering and Coherent OTDR, Interferometric Vibration Sensing (DVS) or other fiber optic sensing technologies.

DTS use Raman scattering to measure the temperature along the fiber. The reflected light intensity of Raman scattering is used to determine temperature measurements.

All technologies have in common that they use optical laser pulses sent into an optical fiber. The pulse travels through the fiber and gets scattered, the part of the back scattered light is received and analyzed at transmitter.

The intensity of e.g. the Raman scattering is a measure of the temperature at a specific point of the fiber. The Raman anti-Stokes signal changes its amplitude significantly with changing temperature. The position of the temperature reading is determined by measuring the arrival timing of the returning light pulse, similar to an echo used in OTDR.

In order to measure strain and temperature Brillouin backscatter signals are used. These systems are called DTSS (Distributed Temperature and Strain Sensing).

The above-described technologies can be used for fire detection over long lengths like in factories, reactors, tunnels, conveyors, factories, airports etc. as well as in high voltage power cable monitoring for buried cables and submarine cables. In Oil&Gas the technology is used for many areas like well monitoring, leak detection, pipe sediment monitoring, flow monitoring and temperature monitoring.

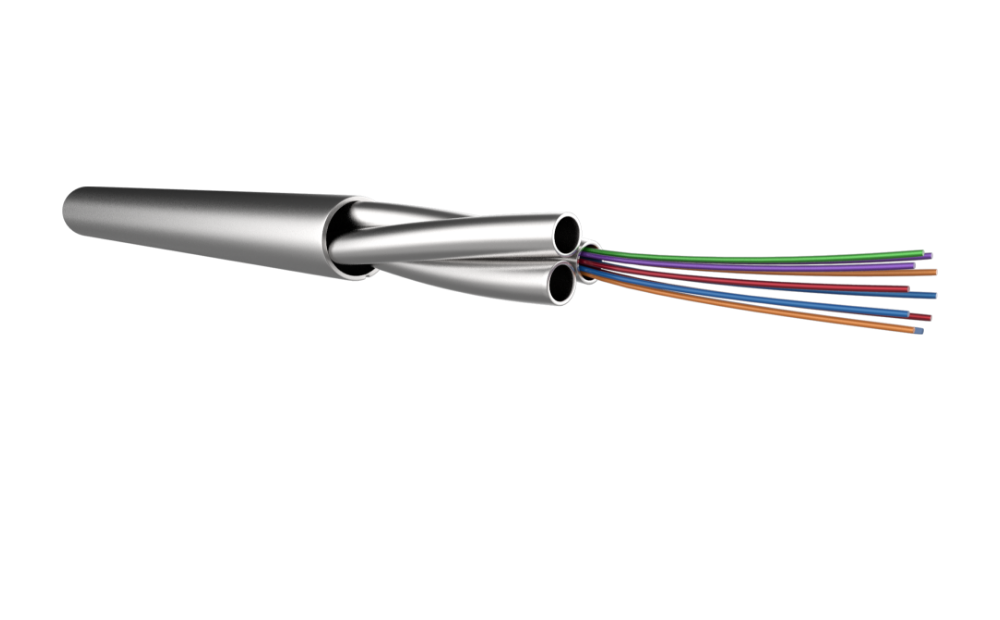

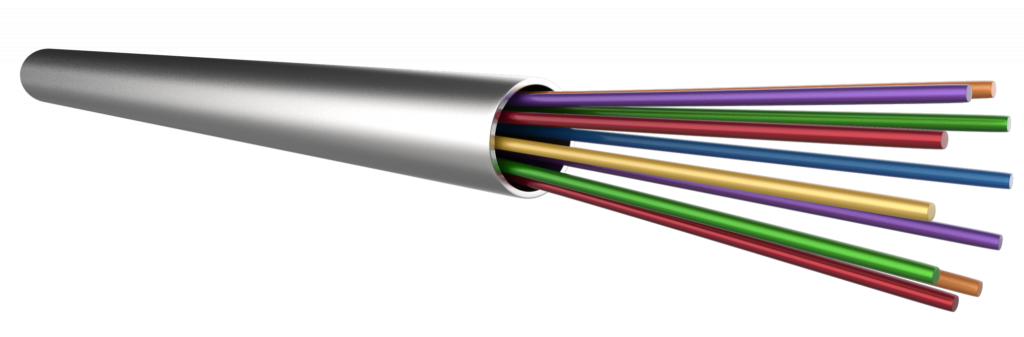

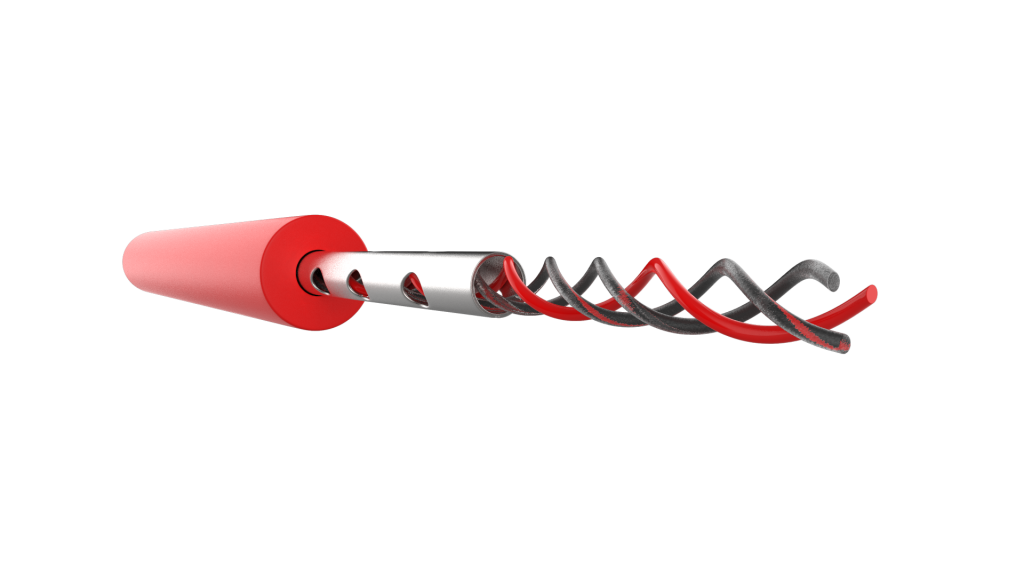

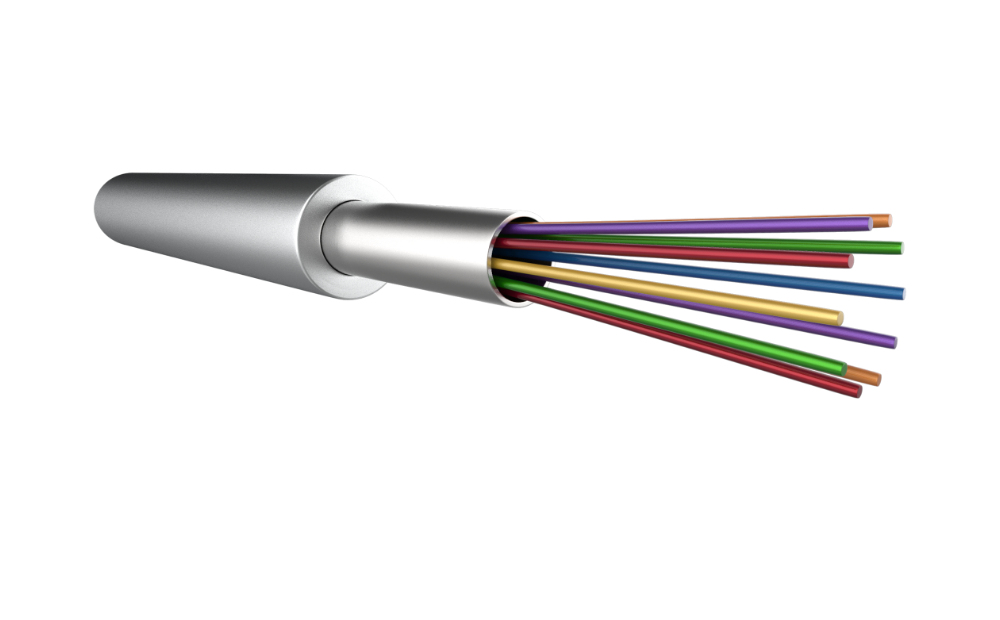

Depending on the measurement tasks many different sensor cable types are available; Some example are shown below: