We do Fusion Splicing of Optical Fibers

OPTIMAL CONNECTIVITY operates its cable assembling workshop for over 10 years. In termination of fiber optic cables we offer direct connectorization, mechanical splicing and fusion splicing.

– What is fusion splicing? –

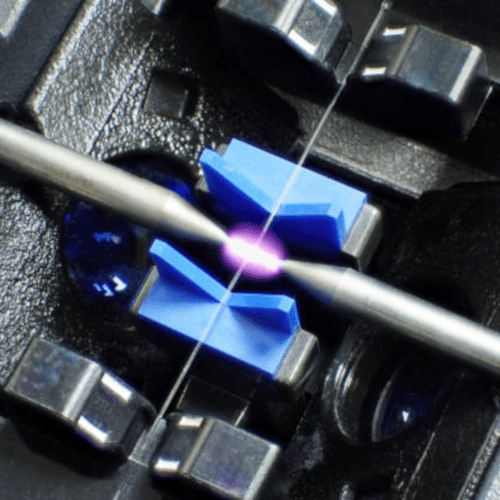

Fusion splicing requires melting together the two sections of a fiber, permanently. It is achieved with a fusion splicing machine, which not only melts the two parts together within an electric arc, but it aligns the fibers properly. Our fusion splicing machine has ample of features which allow us to influence and to match the optical pattern of the splicing area. This is important in case different fiber types need to be spliced together.

Fiber optic fusion splicing is the best way to permanently combine 2 fibers. Our trained staff is able to create splices with less than 0.05dB loss. Compared to mechanical splicing which is more for emergency and temporary fixing of a fiber the 2 fiber pieces are mechanically aligned inside the splicing connector. A typical insertion loss with mechanical splicing at around 0.2-0.75dB, this originates from the fact that these fibers are technically just aligned and not connected physically.

In hazardous areas like EX- areas, we often have restrictions which do not allow us to perform fusion splicing. In such cases we provide our custom-made assemblies or install mechanical splices.

– However, whenever we can, we do fusion splicing –

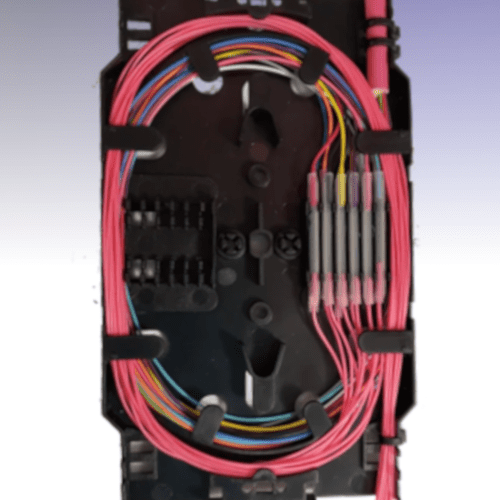

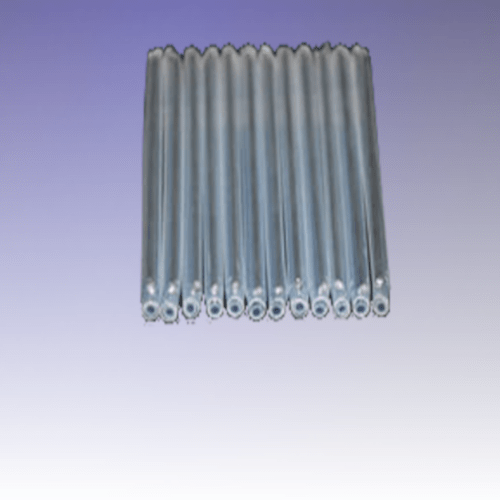

After each splicing process, the splicing area will be mechanically protected. Finally, the entire fiber link loss will be determined and documented using an OTDR.

OPTIMAL CONNECTIVITY serves telecommunication companies, service providers, industrial plants, Oil&Gas, data centers, financial institutions, stock market, research institutions and government agencies.

Please tell us about your requirements for fiber optic splicing service.